ALNAT™ Heat Treatment Solutions

Your reliable industrial partner in a competitive environment

For our customers processing metallic parts or modules in a competitive environment, ALNAT™ offers a reliable solution to meet sustainable development standards (less noise, oil fumes, particulate emissions and no Volatile Organic Compounds (VOCs) while increasing production performance (reduce rejects).

Our Complete Heat Treatment Offer

Ready to support your business

ALNAT™ Heat Treating Performance Solutions

Annealing

| Gas Composition | ALNAT™ Solution | |||

|---|---|---|---|---|

| Neutral | N₂ | ALNAT™ P | ||

| Bright | N₂ N₂ - H₂ Mix H₂ |

ALNAT™ P | ||

| Non Decarburising | N₂ - H₂ - CₙHₘ Mix | ALNAT™ P | ALNAT™ Endo | |

Hardening

| Gas Composition | ALNAT™ Solution | |||

|---|---|---|---|---|

| Neutral | N₂ | ALNAT™ P | ||

| Non Decarburising | N₂ - H₂ - CₙHₘ Mix | ALNAT™ P | ALNAT™ Endo | |

Carburising

| Gas Composition | ALNAT™ Solution | |||

|---|---|---|---|---|

| With Quenching | N₂ - CO - H₂ - CₙHₘ Mix | ALNAT™ C | ALNAT™ Endo | |

Vacuum Carburising

| Gas Composition | ALNAT™ Solution | ||

|---|---|---|---|

| With HP Gas Quenching | C₂H₂ | ALNAT™ HP | |

Carbonitriding

| Gas Composition | ALNAT™ Solution | |||

|---|---|---|---|---|

| With Quenching | N₂ - NH₃ - N₂O Mix N₂ - NH₃ - CO₂ Mix |

ALNAT™ C | ALNAT™ Endo | |

Nitriding

| Gas Composition | ALNAT™ Solution | ||

|---|---|---|---|

| With Quenching | N₂ - NH₃ - N₂O Mix N₂ - NH₃ - CO₂ Mix |

ALNAT™ N | |

Nitrocarburising

| Gas Composition | ALNAT™ Solution | ||

|---|---|---|---|

| With Quenching | N₂ - NH₃ - N₂O - CₙHₘ N₂ - NH₃ - CO₂ - CₙHₘ |

ALNAT™ NC | |

Oxidation

| Gas Composition | ALNAT™ Solution | ||

|---|---|---|---|

| N₂ - H₂ - H₂O Mix | ALNAT™ P | ALNAT™ Black | |

Sintering

| Gas Composition | ALNAT™ Solution | |

|---|---|---|

| N₂ - H₂ Mix N₂ - H₂ - CₙHₘ Mix H₂ |

ALNAT™ P | |

Brazing

| Gas Composition | ALNAT™ Solution | |

|---|---|---|

| N₂ N₂ - H₂ - H₂ Mix |

ALNAT™ P | |

Sub-Zero Quenching

| Gas Composition | ALNAT™ Solution | |

|---|---|---|

| Liquid N₂ | ALNAT™ Cryo | |

More about each ALNAT™ Solution

Promote cleaner processes

ALNAT™ HP and ALNAT™ N| Solution | Features | ||||

|---|---|---|---|---|---|

| ALNAT™ HP | Achieve high pressure gas quenching to suppress oil quenching and fumes | ||||

| ALNAT™ N | Reduce ammonia content in nitriding atmospheres while increasing the nitriding speed | ||||

Increase productivity

ALNAT™ P, C, N and ALNAT™ Endo| Solution | Features | ||||

|---|---|---|---|---|---|

| ALNAT™ P, C, N | Optimise the parameters of annealing, carburising and nitriding processes | ||||

| ALNAT™ Endo | Perform high quality tube annealing | ||||

Contribute to quality improvement

ALNAT™ Expertise, ALNAT™ Performance and ALNAT™ Cryo| Solution | Features | ||||

|---|---|---|---|---|---|

| ALNAT™ Expertise | Control process parameters with gas analysis | ||||

| ALNAT™ Performance | Monitor and control heat treating process | ||||

| ALNAT™ Cryo | Reduce the residual austenite after quenching | ||||

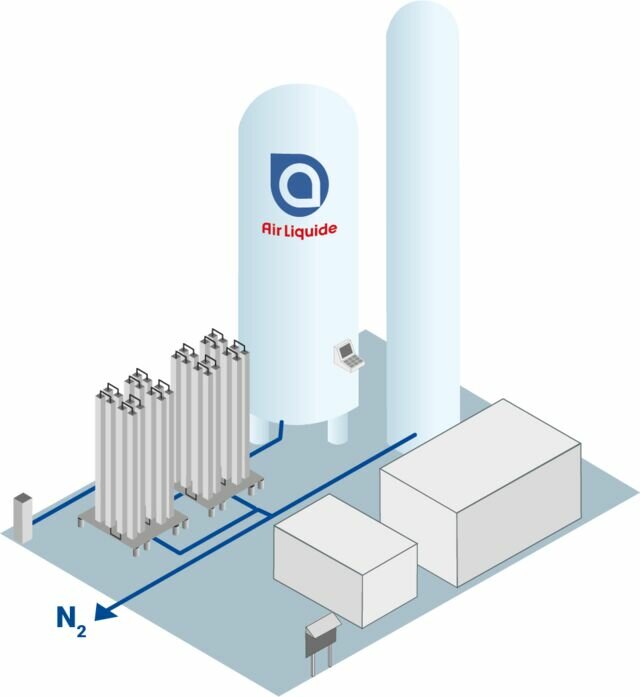

Product Packaging Options

To suit the demands of your business

|

Packaging Types |

Cylinder |

Pallet |

Micro Bulk |

Bulk |

Onsite |

|

Monthly Consumption Rate (Rate to be used as reference only)

|

up to 500 Nm3 |

up to 1000 Nm3 |

up to 5,000 Nm3 |

up to 500,000 Nm3 |

up to 6,000,000 Nm3 |

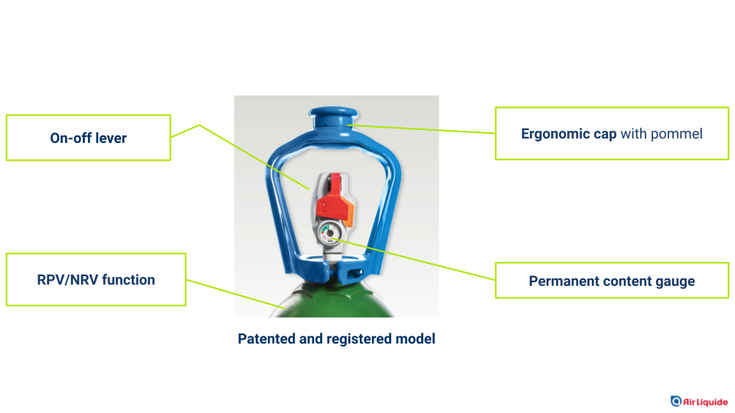

Premium Cylinder TOPs

Focusing on simplicity and safety

A smart residual pressure valve with on/off lever and a permanent content gauge

- Smooth and safe opening and immediate gas cut-off

- Ergonomic cap with pommel for easy handling

- Gas content monitoring at a glance

- Prevents back-flow contamination

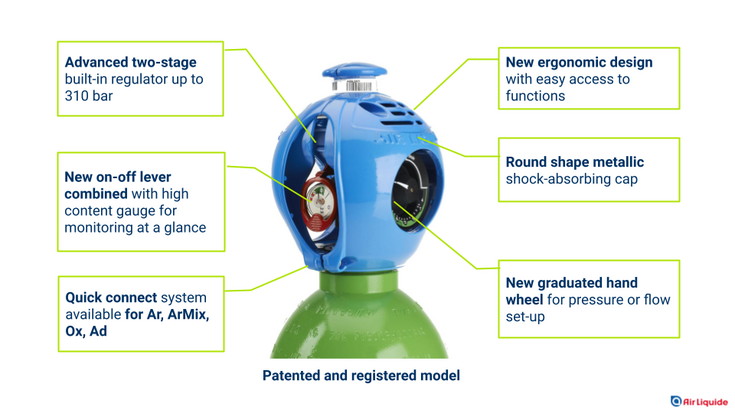

An advanced two-stage built-in regulator with on/off lever

- No need for a separate regulator

- No gas loss and gas content monitoring at a glance

- Quick connect for all gases

- Key safety features

- Intuitive to use

Get Answers

Our team is ready to recommend you a best fit set up